BoostaBoiler, a Technical Overview

The following information is for anyone who would like to understand more about the science behind BoostaBoiler. We will explain how it conditions hydrocarbon fuels on a molecular level to save you money on your energy bills while reducing your carbon footprint.

Let’s begin by thinking about how combustion in a boiler typically occurs.

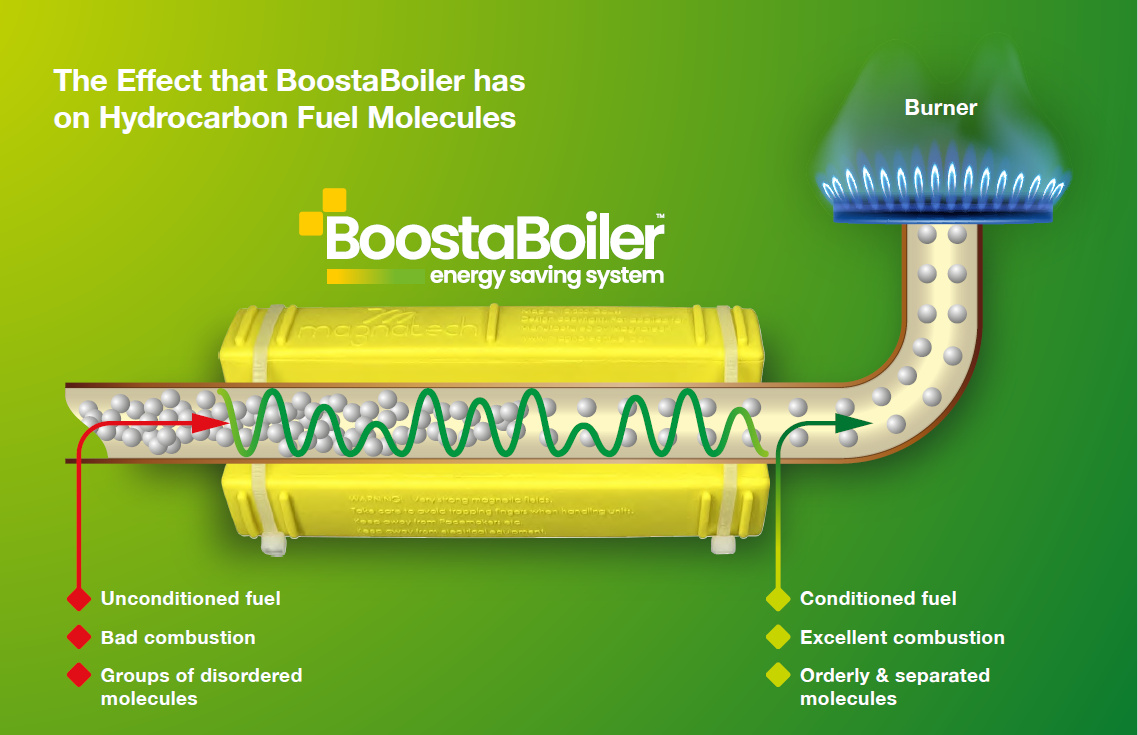

To achieve combustion of the fuel (gas, oil or LPG) supplied to our boiler, and to therefore get the release of heat that we want, it requires the fuel molecules going into the boiler’s burners to meet with, and react with, oxygen molecules from the air supply also coming into the boiler. However, under normal circumstances, the molecules of hydrocarbon fuel flowing into your boiler will generally be clustered together in random, jumbled clumps due to intermolecular attractive forces between them, known as London forces.

Consequently, many fuel molecules remain stuck inside their clusters and never get to meet with, let alone react with, an oxygen molecule. This makes combustion of all the individual fuel molecules entering the boiler far from guaranteed. The result is haphazard and inefficient combustion.

However, in recent years, a number of academic research teams across the world have studied the effects of using very strong magnets on hydrocarbon fuel feed-pipes and have discovered two key benefits, which apply to all hydrocarbon fuels.

Firstly, passing fuel through a powerful magnetic field disrupts the bonds between the clustered fuel molecules and reorients them for a short time so they can more easily combine with oxygen in the burner.

Secondly, the intense magnetic field also stretches the carbon-hydrogen bonds within each hydrocarbon fuel molecule. This stretching makes these bonds weaker and much more likely to react with an oxygen molecule when they are exposed to the heat of the boiler’s burners.

These beneficial effects result in more of the fuel molecules getting burned within the burner. Therefore, a hotter flame is produced with less unwanted CO and NOx emissions because the combustion process is more complete. This is a process known as fuel conditioning.

BoostaBoiler uses a specially designed array of mixed polarity neodymium magnets which create a very powerful non-homogeneous magnetic field. When fuel gas flows through it’s magnetic field, BoostaBoiler has been shown to improve combustion in domestic boilers.

The effect of BoostaBoiler’s fuel conditioning process on a boiler’s flame is demonstrated in this short video.

Conclusion

The two very helpful outcomes from achieving a hotter flame during the combustion process are both verified by published research findings.

One, a hotter flame means that for the same physical amount of fuel going into the burner, more heat output is achieved. Or to put it in the context of your boiler at home, because the flame is hotter, less fuel is needed to heat the water in your boiler to the same temperature, therefore costing you less money to keep your hot water tank and central heating system at the same temperature as before.

Two, a hotter flame means that the fuel burns more completely in the burner. This means that less of the fuel molecules are left unburned or partially burned. Partial burning is not good as it produces noxious gaseous by-products, including carbon monoxide, nitrogen monoxide and other nitrogen oxides. In contrast, more complete combustion results in less pollution being vented from the boiler flue which is obviously much better for localised ground-level pollution and also for atmospheric pollution as a whole.